Energy

Innovations in Desert Ecosystems

Urmul Trust and Selco Foundation have partnered with the agenda of enhancing alternative livelihoods and desert livelihood value chains under the programme Energy Innovations in Desert Ecosystems.The project envisions investing resources commitments in the existing social enterprise value chains promoted by Urmul organisations, with sustainability and renewable energy impetus. We aim at promoting sustainability mandates in the desert value chains and amongst the leaders through this multi-year programme. The aim of this partnership is to deepen the incubation, consolidation and strengthen desert value chains. This will develop new employment opportunities for the desert community thereby directly enhancing the incomes of current practitioners.

Promoting

Sustainability in Desert Value Chains

The aim is to experiment with and develop desert relevant renewable energy models, prototypes and resource pool for continuity towards energy efficiency. This is visualized to be achieved by investing in social enterprises through various activities of innovation, research & demonstration, replication and scaling. The programme is undertaking several energy efficiency, built environment and value chain consolidation activities including infrastructure development towards sustainable enterprises, with cost and energy efficient processes, powered by renewable energy. The project aims at a qualitative and measurable impact in the identified value chains of Crafts, Agriculture and Pastoralism.

Value Chains

-

Crafts

Urmul crafts centers at village level are being made available for many basic and many technical (crafts) upgrades to improve the output qualitatively and quantitatively, eventually leading to higher income opportunities for artisans. Energy for operations, lighting and thermal comfort, post-production QC and finishing is giving a new vertical of utility to these centers. Solar energy intervention in lighting and operational power is optimizing the unit productivity. Innovation and access to semi-automatic looms and other machinery is ensuring product improvement and development of new product segments

-

Agriculture

Bikaner is rapidly growing as an important mustard oil producer but there still is significant drudgery involved. The oilseed mills are heavily inefficient and completely rely on grid power. This makes the operative costs surge and with higher incidents of downtime. Investment in renewable energy in this sector will benefit both in energy access and cost saving at value addition thus directly benefiting the producer and eventually the farmers. Urmul’s demo farm and organic farming training centre at Bajju, is being used for all the demo, research and to scale interventions.

-

Pastoralism

Pastoralism is perhaps the most compromised sector today facing apathy of the system. The pastures are shrinking and community-pastoralists relations are losing the vibrancy. Amidst such scenarios, development of a Common Facility Centre is an innovation Urmul is proposing. Fully developed, the CFC would be serving hundreds of pastoralists and their thousands of animals from the vicinity of the center and also the travelers. The CFC is envisioned to offer services, space and products to pastoralists at nominal maintenance costs.

Efficiency and Efficacy

We are working to deploy sustainable energy as a catalyst to address a plethora of challenges in the desert, relooking at end-use energy requirements, and thereafter developing and demonstrating tailored energy solutions to productivity, living environment and access to key services. Mapping these challenges and opportunities we have undertaken activities under three broad verticals:

Activity advancement through business process or plan development

- Setting up a Desert Innovation Fund to give soft institutional loans to enterprises for promoting renewable energy and enhance efficiency and innovation in the value chain.

- Consolidating and qualitatively enhancing the product line across the crafts value chain with installation of advanced machinery, bringing in renewable energy sources for lights, fans, etc and built environment initiatives.

- Research and development of activities to education and installation of biogas units, cattle feed units and setting up agro-farm.

- Facilitating the construction and mechanisation of milk storage and processing units, installation of advanced shearing facilities and renewable electricity sources at Common Facility Centres for pastoralists.

- Converging with other Urmul Programmes for leveraging knowledge and exploring partnerships to foster institutionalisation.

Data driven field visits

Vendor and technology identification

Stories that inspire change

-

Biogas Plant Setup in Khetolai

Over time, people in rural areas have been dependent on unsustainable sources of energy, and especially wood burning. This has resulted in emission of greenhouse gases and over the years has depleted the ozone layer. This problem is aggravated when the already limited wood in desert areas are used for cooking and other daily chores. Considering the present scenario and with an aim towards sustainability, a Sistema-30 biogas model was installed in Bhagirath Ram’s house connecting to 3 nearby houses in Khetolai village, Pokaran, Jaisalmer district. The model requires 260kilograms of cow dung every day which is provided by the 4 project focused families. In return, the families get 19hours of biogas and 780litres of biofertilizer per day which is used as organic fertilizers for the kitchen gardens. As a result, cumulatively 25 people are using this sustainable mode of energy production and reducing the monthly cost for each family by 1500INR. This has disregarded the need for LPG cylinders and wood burning which has been both cost intensive and environmentally detrimental.

“The biogas model has been a landmark achievement in our village. This initiative has reduced our household waste and produced gas for which we used to spend a lot of money. All the neighbouring families have asked us about this set up and are eager to adopt it.”Bhagirath Ram

-

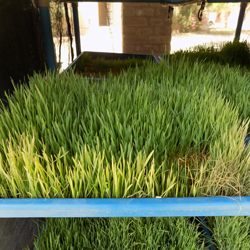

Hydroponics Setup - Hydroponic Setup

The slim possibility of green fodder in arid and semi-arid regions is aggravated by problems of land fertility, insects and pests. The extreme heat and drought has made things worse for both the breadwinners and the livestock of Thar . With an initiative towards revitalizing the production of green produce and effectively addressing the issues around water scarcity, land degradation, a hydroponic unit has been set up at Urmul campus, Bajju. As a result, 966kilos of wheat and jowar is produced in a month. The produce is then provided to the cattles which facilitates the milk requirement of 60 people on the campus and has prospects for milk derived products. In addition, the water used for hydroponic is mixed with organically prepared nutritive liquid extracted from vermicompost manure made at Urmul Farm.

Moreover, since hydroponic plants are not grown in soil, the challenge of soilborne diseases are zero to none, simultaneously the yield per 100 litre of water increases by more than 300% as compared to traditional farming and the produce only takes about 8-10 days.

“Now, we don’t have to buy industrial chemicals or wait for rainfall. Also, we are using very less amount of feed from the market. Moving forward, we can produce wheat at any time of the year as required by the cattles.”Achla Ram, Livestock owner

-

Promoting Green Built Environmen

BMC Bajju - Considering the extreme heat and several other factors like carbon footprint, we have devised sustainable mechanisms and promoted the use of local alternative materials to reduce the price as well as to provide structural stability that will sync with the desert context. By adopting rammed earth technique, the usage of natural raw materials like lime and sand have increased and simultaneously cut down logistic cost and the use of cement and bricks. Moreover, the lime used is processed locally at the Bajju campus. The usage of local raw materials and the rammed earth technique would be vital for temperature moderation. Considering this learning, the team has also applied the techniques in the 4 craft centres of Dandkala, 7 AD, Gokul & Deli Talai and 26 BLD. Moreover, materials like glass bottles and new techniques such as rat trap bond is also used to disregard the logistic and extra material cost. At the Urmul Dairy, a wall is constructed entirely of glass bottles to reduce the use of bricks and cements. Furthermore, two looms in Napasar is powered by solar energy and is providing daily income to the local artisans.

“This weaving unit has provided employment to a lot of local artisans, we are happy about the solar loom, frequent power cuts won’t be a problem anymore. However, we think of this just as the beginning, as we move forward we will bring significant changes for our artisans.” Om, artisan at Napasar, BikanerOm, artisan at Napasar, Bikaner